The Illusory Learning Curve

If you are unable to understand the cause of a problem, it is impossible to solve it.[Naoto Kan]

Figure 1. Dangote hydrocracker, 8.5 meters in diameter, 60 meters high.

In the last post, we talked about the astonishing productivity of a world class shipyard. Less than 5 man-hours to cut, weld, erect, and coat a ton of complicated steel structure. About 10 man-hours per ton delivered. One of the amazing things about shipyards is they achieve this productivity despite the fact that every ship is a one-off. There are almost no specialized jigs or tooling anywhere in the yard. The only thing the yards save when they build a series of identical ships is the design time. There is no learning curve in the usual sense. There is slow technical progress in the yard production process as a whole, e.g. gradually introducing more robotic welding.

If nuclear power plants were built in a shipyard, much the same thing would apply. Corollary: the first one better be cheap, because the second one and the tenth one will cost about the same.

Nearly the same thing applies to site built power plants. The main difference is that, if multiple plants are built at the same site in the proper sequence, there is a one time savings in mobilization costs. But as far as I can tell, it is in the range of 10 to at most 25% of the initial plant cost. It is essentially exhausted after two units are built. And if you try to build a lot of plants quickly, you will turn the vendor markets against you. This happens in shipbuilding every time the tanker market goes into boom. Ship prices double and triple, but the yard margins don't change that much.

But nuclear power plants are different you cry. Nonsense I reply. The technical skills and physical supply chain required to build a nuclear power plant are a combination of those required to build a coal plant and a refinery.

What about the reactor pressure vessel you bray? Have you been to a refinery I say? The reactor and the steam generators are dwarfed by the pressure vessels in a refinery. For example, the hydrocracker at Total's Gonfreville-l'Orcher is 42 m high and 5.5 m in diameter.1 It operates at 180 bar and 454C. The wall thickness is 0.267 m (10.5 inches). And it's not the largest. 100's of similar pressure vessels are scattered all over the planet.

The APR1400 reactor pressure vessel, one of nuclear's largest, is 14.8 m high, 5.1 m in diameter with a wall thickness of 0.193 m. It operates at 155 bar and 334C. Nothing special by refinery standards. What's truly amazing about a reactor pressure vessel is how tiny it is for its power output.

There is no real learning curve for fossil plants nor refineries. Ergo, don't expect much of a learning curve for nuclear plants. And in fact with the exception of nuclear power's birth decade, 1955-1965, and maybe the first few plants in Korea, we have never really seen one.

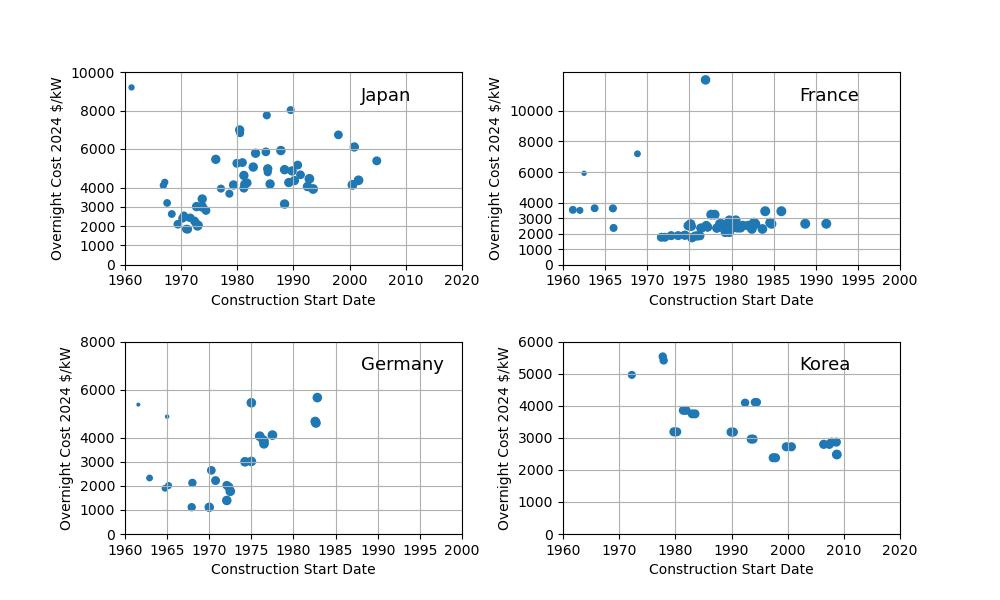

Figure 2. Overnight Costs in 2024 dollars. Lovering database.\cite{lovering-2016}

Some uppity choristers will claim it's there; but it has been overwhelmed by increasing regulation. This could be true for the US. The preposterous increase in regulation in late 1960's and 1970's, would overwhelm any learning curve if there was one. But French nuclear in the 70's and 80's was essentially self-regulated by EDF. Real cost increased during that period, Figure 2, possibly due to tight vendor markets. Germany is worse. Don't know why. Japanese regulation was reasonably stable between 1980 and Fukushima. There is no sign of a learning curve in that period. Korean regulation has been pretty stable. We do see some decline in the first few plants, but nothing much since then. This is about as close to a nuclear learning curve of which I am aware.

More than ten AP1000's have already been built or are under construction. There is no clear pattern to the real cost. But I know of no US utility that is jumping at the chance to take advantage of whatever Westinghouse learned at Vogtle and VC Summer and elsewhere, despite the availability of massive IRA tax credits. EPR costs have increased on each of the first 5 units, and will increase again at Hinkley C.

It is possible to cite special circumstances in some of these recent examples. But the one thing we can say for sure is in each case the vaunted learning curve was too feeble to outweigh those circumstances. The learning curve for nuclear power plants is weak to non-existent, just as it is for coal plants and refineries. Yet the nuclear engineers at MIT are claiming that the 10th American AP1000 should cost 24% of Vogtle 3 and 4.\cite{shirvan-2022} This 2022 study puts the did-cost of Vogtle 3/4 at $12,200 per kW and the should-cost at $2900 in 2018 dollars.

But MIT's Vogtle should-cost is not a learning curve number. The study puts a lot of emphasis on learning curves, but a careful reading shows they only claim about a 25% reduction in cost between First of a Kind and Next (10th) of a Kind. Their should-cost is a bottom up number, based on material and labor requirements. The Gordian Knot Group (GKG) overnight should-cost per kilowatt for an AP1000 is in the low 2000's. We are in the same ball park. MIT is right. Nuclear power should be cheap.

But the GKG is out front. The GKG admits its should-cost assumes we regulate nuclear power much like we regulate coal plants and other potentially hazardous activities. It’s a competitive market number. MIT at least implicitly assumes no material change in regulation. How does MIT explain the ridiculous factor of four difference between its should-cost and its did-cost (which turned out to be low)?

It doesn't really say. There are passing references to one-off costs, Covid, and "regulatory inefficiencies", but no real exegesis of this preposterous, all important difference. And with all the blather about learning curves, a casual reader can be forgiven for thinking learning curve, which many have. Why would MIT direct the reader's focus away from the real problem, a tragically misdirected, omnipotent regulatory system, to a semi-bogus, secondary factor, which by their own numbers cannot come close to explaining Vogtle's outrageous did-cost?

In their own minds, they had no choice. They cannot blame the real problem. These people believe the Two Lies. They think NRC style regulation is both necessary and a good thing. And if any of them have their doubts, they cannot afford to upset the system that feeds them. NuScale burst the SMR bubble (as the MIT study correctly anticipated). They have nothing left but the learning curve.

Whether it's indoctrinated falsehoods or narrow self-interest, the result of the nuclear establishment’s inability to identify the real cause of US nuclear’s failure to live up to it promethean promise will be the same. The US will be saddled with a trickle of exorbitantly expensive nuclear, largely funded by the taxpayer. In that case, the nation would be better off if we had none at all.

A hydrocracker reacts hydrogen with the dregs of the distillation column at high temperature and pressure, to transform low value heavy fuel oil to higher value diesel and jet fuel.

Fantastic post. Hey, given all these recent EOs, what’s your wager that this administration actually cuts the Gordian Knot?

great article.

The Canadian experience was a little different than the US. The Canadian regulator, the CNSC, was possibly less prescriptive than the NRC. The CNSC accepted that the early reactors like Pickering worked adequately. However, the CNSC became more and more unaccepting of new designs of components or systems. For example when Darlington tried to introduce a computer based shut down system, to replace a relay based hardware system, it became a billion dollar plus exercise. Everyone agreed this was a great idea, but try to get it accepted. People that went through the process stated they never wanted to do that again. Pickering got the rights and parts to rebuild a 1965 era large scale computer instead of replacing it with a tiny cheap computer because that was overall cheaper. This process of demanding ever increasing levels of QA and testing on new developments meant reactors could not take advantage of learning curves. In the end (2000-2007) we could not get a 10 MW thermal pool type reactor licensed.