Nuclear power is too slow

One common and plausible argument against nuclear power is that it is too slow. The evidence offered is recent interminable builds in the US and Europe, Table 1. But is this inherent in the technology?

The American Disaster

In the USA, Figure 1 prior to 1966, the build times were 4 years or less, with two exceptions. Fermi 1 was a one off, a sodium cooled, fast breeder, basically an experimental reactor, in which the core overheated due to a last minute safety add to prevent a problem that later was proven impossible. The plant was shut down for four years to correct this. I do not know what went wrong at Indian Point 1.

Figure 1 USA Build Times. Red dots are average for that start year. Area of blue dots is proportional to plant capacity. 17 years plus not shown. Data from IAEA PRIS database.

But after 1966, build times deteriorated rapidly. Plants started in 1968 had an average time to grid connection of about 7 years. By 1970, this was up to 8 years. By 1972, it was close to 12 years. Time to grid connection peaked for plants started in 1973 at about 16 years. After 1973, there was some recovery, but build times remained over 8 years for almost all the late 1970's plants, The scatter for functionally equivalent plants is preposterous. In any given year, the low to high range is better than a factor of two. Since the 1970's were a period of very high interest rates, this escalation in build times was a major contributor to plant costs.

Some of the worst performers involve site specific issues including court ordered delays, engendered by anti-nuclear groups. But this was a post-1978 phenomenon, and not the case for the bulk of the plants, and certainly not the better performers in each start year.

This regression defies conventional wisdom. The much vaunted learning curve should have resulted in reduced build times (and reduced costs) as a nascent industry gained experience. Instead precisely the opposite happened. There were two basic problems:

1) An ordering boom which started in 1966 as oil prices began to climb.

2) ALARA based regulation.

In 1965, the US had less than 2 GW of nuclear plants under construction. Five years later that number was 57 GW's, Figure 2.

Figure 2. USA Nuclear Gigawatts Under Construction

To support this massive ramp up, the industry was counting on the extraordinary industrial base that the US had developed in World War II. However, light water reactors require some highly specialized skills. The most obvious of these is the reactor pressure vessel. Going into 1966, there were only two vendors which had the capability of welding together these heavy forgings: Combustion Engineering and Babcock and Wilcox. Both expanded to meet the demand. But the Babcock and Wilcox expansion, which involved a greenfield site in Mount Vernon, Indiana was a tragic flop, a plethora of errors which led to the grisly suicide of the plant manager. The result was a multi-year delay in the delivery of over 20 of the pressure vessels. Other vendors experienced significant if less dramatic teething problems.

However, after 1970 the work load leveled out. At this point we would expect the learning curve to kick in. But it did not. Construction times continued to skyrocket, and costs climbed with them.

The truly unique feature of US nuclear power is the unlimited power that was given to federal regulators. In this case, the regulators came up with ALARA, the principle that no level of radiation exposure is acceptable if the plant can afford to reduce it further. As oil and coal prices rose through the 1970's, ALARA guaranteed that nuclear costs would rise accordingly. ALARA inspired design changes also extended construction times.

Worse, Congress had effectively told the regulator make the rules up as you go. This meant the regulator had no problem changing the rules. A design that was legal at the start of construction, could be declared illegal any time thereafter. This backfitting often meant redesign, ripping out portions of partially completed plants, and then repeating the process. In the USA, the learning curve never had a chance.

The French Decarbonization

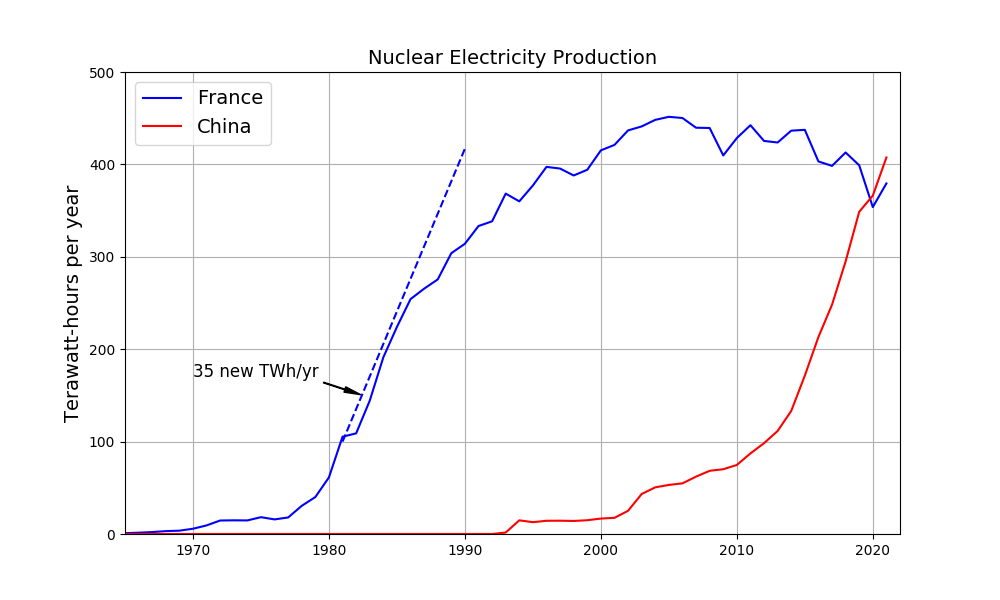

The French were able to hold their build times below 6 years up to about 1985, Figure 3, with very little scatter. In the 1980's, France was adding 35 TWh's of new nuclear power production each year, Figure 4. France's annual electricity demand at that time was about 350 TWh. France was decarbonizing her grid at the rate of 10% per year.

Figure 3. French Build Times. Data from IAEA PRIS database.

After 1985, things began to deteriorate. According to the learning curve, build times should be dropping with added experience. We cannot blame blame escalating regulation for this fall off. EDF, the state owned utility, was given complete control of the project. It was essentially a form of self-regulation. But EDF is a monopoly, beset by strong unions. As the initial momentum wore off, all the standard monopolistic inefficiencies set in. The reduction in the build rate after 1985, which in a competitive market would have reduced costs, instead required build periods to be stretched out to keep everybody busy. After 1995 with no competitive pressures, things completely fell apart.

Figure 4. French and Chinese nuclear electricity production. Source BP Energy Review.

Japanese Discipline

It is the Japanese that really put the lie to the claim that nuclear has to be slow. They built 60 plants between 1970 and 2009, Figure 5. The median build time was 3.8 years, which is about the time it takes to build a big coal plant. There is no sign of a learning curve in Figure 5. But there is also no sign of a fall off. The Japanese system involves shipyard-like competition. The two big players have been Mitsubishi and GE-Hitachi. Other entrants such as Toshiba are always prowling around. While we might expect some form of cartelization in both shipbuilding and power plant construction, effective competition has been maintained in both cases. And in the Japanese case, the regulators have not played an American style dominant role, at least not until after Fukushima.

Figure 5. Japan NPP build times. Monju and Fugen ATR were experimental. Graph courtesy of Geoff Russell. Data from IAEA PRIS database.

There is nothing inherent in the technology that says a nuclear plant should require any more time than a coal plant to build. In both cases, the critical path is dominated by the turbogenerator. The reactor pressure vessel, steam generators, and pressurizer are all far more compact than a coal plant boiler, and can be manufactured in less time than the turbine. In the right environment, nuclear power can be deployed as quickly as coal, as the French proved. Sweden also completely decarbonized her grid between 1970 and 1986.

On the other hand, the whole learning curve concept for power plants appears to be over-rated. Coal plants show little sign of a learning curve. Rather we see slow, incremental, technological improvements, that over time add up. The French did not see much of a learning curve during the period in which EDF was in total control. Nor did the Japanese ever. If there is a learning curve in on site construction projects, it is largely exhausted in unit or two. Those who are betting on the learning curve to markedly reduce current exorbitant nuclear costs and interminable build times, are very likely to be disappointed. What's required is regulatory stability and competition.

Not without a complete change in regulatory philosophy. That's why ThorCon had to go overseas.

But this site is not about ThorCon, and I will not respond to any questions about ThorCon here.

SONGS 1 ~500MW built in just over 3 years- IN CALIFORNIA. Can you even imagine that today?!?