Nuclear Power not only should be cheap; it was cheap: 3 cents/kWh cheap.

This piece is a slightly abbreviated version of the nuclear cost chapter from the Make Nuclear Cheap Again book. A PDF can be found at Nuclear Cheap chapter.

Nuclear power in the West is a disastrously expensive mess. Table 1 shows where we are. Only the wealthiest nations can afford these kind of costs, and then only sporadically. The construction times are such that there is no way nuclear can put a dent in global warming, or anything else. And it keep getting worse. NuScale the first of much vaunted and highly subsidized Small Modular Reactor's is the most expensive of the lot; and it has not even been built yet. If this is the way things must be, nuclear power is a dead end.

But does it have to be this way? A 1 GW coal plant must process, dry, and pulverize roughly 7000 tons of coal per day. This coal is fed from a 30 hectare (70 acre) yard, Figure 1, dried, pulverized, and mixed with over 77,000 tons per day of heated air that :has been pushed into a 90 meter high boiler by immense forced draft fans. The coal yard in turn must be fed by a 100 car train nearly every day or a 150,000 ton bulk carrier every two or three weeks. Often the coal has been transported thousands of miles from a huge open pit mine.

Figure 1. Manjung 4 coal plant looking seaward

For an average good coal, the process produces roughly 1100 tons a day of solid waste (mostly fly ash) and 200 tons per day of sulfur dioxide. The 84,000 tons per day of stack gas is pulled though an air heater, a SCR unit to remove most of the NO2, a giant baghouse or electrostatic precipitators to remove most of the particulates, and pushed into a scrubber by immense induced draft fans to remove most of the SO2. SCR (Selective Catalytic Reduction) requires ammonia be sprayed into hot flue gas, and then the gas be directed through a catalytic honeycomb which must be kept free of plugging with sootblowers and sonic horns. The baghouse or precipitators require shakers or rappers to remove the ash, most of which goes to landfills or slurry ponds. Scrubbers require about two tons of pulverized limestone per ton of sulfur in the flue gas. They are high maintenance, energy intensive units. They add a little CO2 to the stack gas. Finally, 18,000 tons per day of CO2, and about 10% of the Gross Calorific Value of the coal is spewed out of the top of a 170 m high stack. The stack height is required to dilute the remaining pollutants in the gas.

Yet in 2015, the German utility RWE commissioned their Eemshaven plant in the northeast corner of Holland at a cost of 2.2 billion euros. This is a little under $1500/kW for a 2 by 800 MW plant, or just under $2000/kW in 2024 dollars. This is for the latest and greatest ultra-super-critical plant meeting stringent EU pollution limits, sited in one of the most expensive places to build on the planet. The rule of thumb is $500/kW for the turbine hall and switchgear. The rest is fuel handling, the boiler, and pollution control

}

Figure 2. Eemshaven: 2 by 800 MW USC coal plant, 46.2% efficiency}

A 1 GW nuclear plant will burn about 82 kg's of fuel per day, producing the same amount of solid waste. That’s about 100,000 times less than the coal plant. The coal yard and the coal receiving terminal disappear, as do the dryers and pulverizers. The nuke's Fission Island volume will be smaller than the coal plant's boiler. The turbine hall will be slightly larger. There will no stack gas handling equipment, no massive Forced Draft and Induced Draft fans, no SCR, no baghouses, no scrubbers, no massive stack. The ash landfill and slurry pond will be replaced by less than an acre of 5.9m(19 ft) high by 3.5m(11 ft) diameter casks. The nuclear plant should be cheaper to build with far cheaper fuel costs.

And indeed, in the 1960's, nuclear's 100,000 to 1 advantage in energy density allowed nascent nuclear power, which was just starting down a steep learning curve, to go head to head with coal. In 1965, GE was able to show TVA that it would produce electricity for less than 3.7 mills per kilowatt hour.\cite{bupp-1978}[page 90] That's about 3.2 cents per kWh in 2024 dollars. Komanoff, no friend of nuclear power, estimated nuclear's 1971 CAPEX at 366 1979 dollars per kW, and coal without scrubbers at $346/kW.\cite{komanoff-1981}[p 20] Nuclear's fuel cost advantage tipped the cost of electricity in favor of nuclear. In 1970, Paul Ehrlich, a determined foe of nuclear on Malthusian grounds, complained ``Contrary to widely held belief, nuclear power is not now `dirt cheap'. ... At best, both [nuclear and coal] produce power for approximately 4-5 mills per kilowatt-hour."\cite{ehrlich-1970}[p 57] In the late 1960's nuclear power was as cheap as coal, when coal was as cheap as it ever was in real terms.

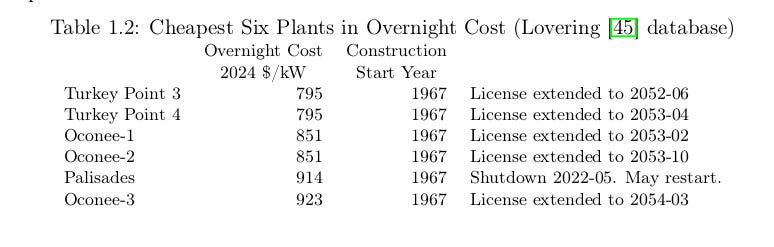

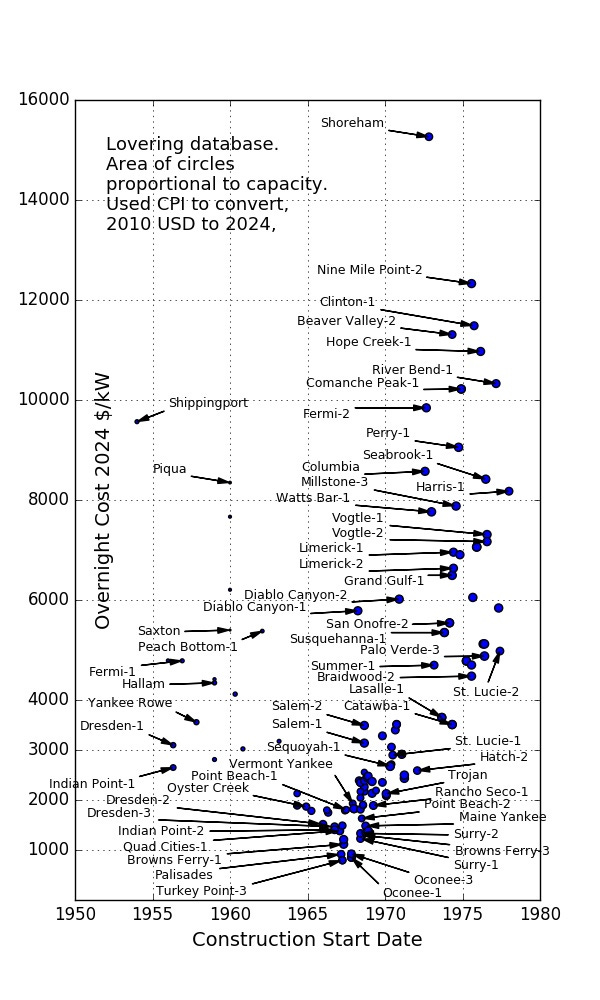

This did not last long. Figure 4 shows the Overnight Cost of USA nuke plants built between 1950 and 1980 in 2024 dollars. The date shown is the date that construction started. Almost all the plants started between 1964 and 1968 came in at under $2000/kW in 2024 dollars. Six of those plants came in at under $1000/kW, Table 1.

Figure 3 shows that if you combine these overnight CAPEX numbers with a four year build time and low risk, interest rates (which requires near zero regulatory uncertainty), a nuclear plant can easily produce base load electricity at 3 cents/kWh in 2024 dollars.

But by the mid-1970's, the same size plants had an overnight cost of up to $10,000 2024 dollars and more with a very large scatter.

Figure 4. Overnight Cost, USA Nuclear Power Plants, adapted from \cite{lovering-2016}}

Overnight costs are only a portion of the CAPEX. At the same times as the overnight costs were skyrocketing, build times were doubling and tripling, Figure 5. Plants that took 4 years to build in the late 1960's were taking 10 or more years in the late 1970's. The 1970's was a period of inflation and high interest rates. Interest expense also skyrocketed.

Figure 5. USA Build Times. Red dots are average for that start year. Area of blue dots is proportional to plant capacity. 17 years and more not shown. Data from IAEA PRIS database.}

During this period the DOE funded a detailed cost study called the Energy Economic Data Base (EEDB). John Crowley was the guy who headed the team that developed and maintained the EEDB. Figure 6 shows Crowley's 1982 estimates of the total CAPEX for American nuclear plants, through the 1970's. The right hand side of the figure are partially projections of what was happening in 1982. The figure is in nominal dollars based on the (projected) year of completion.

Figure 7 translates these numbers into 2024 dollars using the CPI. Crowley's numbers show a factor of three increase in overnight CAPEX, greatly exacerbated by the increase in build times. The total CAPEX increase in real terms is a staggering factor of 10.

Figure 6. Crowley's 1982 estimates of USA Nuclear Power Plant CAPEX, in nominal dollars.\cite{crowley-1982}}

Figure 7. Crowley's estimates converted to 2024 USD.

How could this happen? Nuclear, a technology that did not exist 15 years earlier, was moving down a steep learning curve as the left hand side of Figure 3 shows. Real costs for plants completed in 1980 should have been lower than for plants completed in 1970. But two things happened. The first was The Oil Crisis.

The factor of five increase in oil prices between 1968 and 1974 priced oil out of the power generation market, creating a boom for coal and nuclear. In this frenzy, both coal and nuclear lost control of their costs. This happens whenever a cyclic market goes into boom. In the case of coal, the cost escalation was exacerbated by a series of strikes and a slew of new environmental regulations.

But this loss of cost control manifests itself mainly in labor and equipment price increases, some loss in labor productivity due to use of inexperienced workers, and longer lead times. A technology does not get worse during a boom. It does not require more material to do the same job. It does not require more design and engineering per unit.

But nuclear's material intensity rose dramatically in the 1970's, Figure 8. Concrete and steel for the same plant doubled. Cabling and conduit for the same plant more than tripled.

Figure 8. Crowley's material estimates, 1971 to 1983

The labor numbers, Figure 9 are even worse. According to Crowley, craft labor went up by a factor of four.\cite{crowley-1985} Paperwork labor went up by a factor of more than ten. Phung, working from essentially the same data, found that things get even worse if you go back to 1967.\cite{phung-1985} In 1980, a 1 GWe plant required three times more paperwork labor than it took real labor to build the darn thing in 1967. Boom congestion and diseconomies cannot explain these outrageous numbers.

And, when the inevitable crash happens and the market goes into slump, as it did in 1979, the survivors get their act together, and eventually real costs return to pre-boom levels. That's what happened to coal, Figure 10, despite increasingly stringent regulation. But not nuclear. Nuke costs leveled off a bit, but they never came down. Something else was happening.

}

Figure 10. USA coal and oil prices, 1949 to 2009, reference \cite{howarth-2009}[page 16]}

Up until the late 1960's, the Atomic Energy Commission's regulation of nuclear power was a tug of war. Attempts to impose regulatory costs were not only strongly resisted by the industry which was in life or death competition with coal and oil, but the AEC itself was caught between its promotional function and its regulatory function. The result was a balance, and the plants built under that balance have a pretty good safety record. These plants have been producing some of the cheapest electricity ever generated for more than 50 years; and no member of the public has been harmed.

But with the doubling and tripling in coal prices, the utilities' goal became do whatever you have to do to get the plants built. Rather than pushback against new regulations, no matter how silly or superfluous and engage in time consuming negotiations, the utilities decided to accept anything they thought they could afford, or pass on to the ratepayer.

In 1972, they even swallowed the Double Ended Guillotine Break (DEGB). In this scenario, a section of the primary loop piping instantaneously disappears. Steel cannot fail in this manner. Ted Rockwell put it best, ``We can't simulate instantaneous double ended breaks because things don't break that way."\cite{walker-1992}[p 179] Designing to handle this impossible casualty imposed severe requirements on pipe whip restraints, spray shields, sizing of Emergency Core Cooling Systems, and emergency diesel start up times (11 seconds to load), requirements so severe that it pushed the designers into using developmental, unrobust technology.\cite{okrent-1981}[page 138] All the money spent on the DEGB probably made nuclear plants less safe. A saner approach is Leak Before Break by which the designer ensures that a stable crack will penetrate the piping before larger scale failure.

As soon as one applicant agreed to a requirement, that became the floor for the next applicant. Rules ratcheted upward with each application, forcing continual design changes. In its most pernicious form, backfitting, the new rules were imposed on plants already under construction. A 1974 study by the Government Accountability Office of the Sequoyah plant documented 23 changes ``where a structure had to be torn out and rebuilt or added because of the required changes."

In 1979, the world economy went into deep recession. Coal reacted to the new reality and steadily reduced its costs in 1980's and 1990's despite new regulation. But the regulatory ratchet works only one way. We are still stuck with the absurd Double Ended Guillotine Break requirement. US nuclear was left stranded with top of the boom costs. It could not and never did recover.

Nuclear power was and should be cheaper than coal. The reason why it is not is a tragically misdirected regulatory system. We give an omnipotent regulator final approval of any nuclear power plant, and judge him on his ability to prevent a release of radiation. He gets no credit for the cheap, pollution-free, CO2-free, on-demand power generated by a successful plant, nor the avoided mortality and morbidity that would have resulted if the plant had not been built. But he owns any problems. The regulator responds accordingly; and, since this autocrat has the final say, it's his incentives, not society's, that determines what happens. The result is technical stagnation, a demoralized workforce, lack of competition, and shoddy quality. The result over time is nuclear power that costs five or more times what it should-cost and build times that are three to four times longer than they need be.

The problem is man-made. What is man-made can be man-unmade. We must dump the current disastrous regulatory system, and adopt a variant of the system that has provided us with the unprecedented wealth and health that we current enjoy. That variant is called Underwriter Certification.

The Aussies are having a FaceBook debate about cost. I posted a comment with some guessed-at numbers needing a fact check. // The best response to people who want to argue cost is "If a vendor offers you a product you want, at a price you like, don't argue, place an order." I like ThorCon's price of US$1200 per kW for a complete 500GWe plant. 80% of this cost is off-the shelf parts, like turbines and generators. If there is a 50% cost overrun on the nuclear part, that is only 10% more on the total.

https://thorconpower.com/economics/ //

Very forceful essay. Basically somewhat like drinking from a firehose. These cost increasing factors do seem to be a major impediment to implementing nuclear power as widely and quickly as a rational assessment would warrant. However, I did not attempt to follow through to the referenced sources you provided. I also scanned* the 101 page pdf for the Underwriter Certification process (recognizing some text from your past recent posts).

Somehow I ended up coming away with a possibly OT question:

What other biological risks are there besides down stream cancer results?

I am thinking mostly in terms of birth defects. I vaguely recall you have already mentioned this is not a major concern - but I forgot why :-( [Lower probably of gamete DNA damage as the sex organs are a small % of total body volume, etc. ??]

*Since I only scanned the doc, I might have missed if you also provided a set of sample payouts. For example, for high, medium, and low exposures. E.g., if you were 10 miles from TMI, you got $X. If 1 mile from TMI you got $Y. If you were within 500 or 1000 yards of TMI you get $Z, plus weekly medical exams for the first 8 weeks, and monthly exams for the rest of the year [or whatever - I just made that up]. I think having a sample/ example was an item I suggested in a previous comment? I suspect even legislative staffers might want to have a story to tell constituents along the lines of "here are some typical benefits", etc.